Product Overviews

PlasETM Clean Series launched purging compound for engineering plastic extrusion, which include but not limit to PA, POM, PBT, PC, etc. The product is specifically designed to effectively clean the machine barrel, screw and die for color change, material switch, carbons cleaning, carbonization prevention and downtime maintenance, which reduces overall purging costs and improves production efficiency.

Customer Relevance

• Does it produce carbons during your machine startup & shutdown?

• Is it difficult when the two plastics switch to each other?

• Is it time consuming and material demanding when you conduct color changes?

• How smooth is your operation when you switch from a high-temperature material to a low one?

• Does it produce heavy smoke & odor when conduct screw purging?

Extrusion Machine Purging Compound for Engineering Plastic Cleaning Basics

• Product appearance: granules

• Function: cleaning of barrel, screw, nozzle, die

• Application: carbon cleaning, carbonization prevention, color change, material switch, downtime maintenance

• Material suitability: PA POM PBT PC etc. engineering plastics

• Temperature: 170-350℃

• Advantages: no foaming, no abrasives, high efficiency

• Package: 25KG/bag

• Environmental performance: very low smoke, environmental friendly

Feature

• Suitable for cleaning of die

• Equipment friendly without foaming ingredients and abrasives

• Highly efficient in terms of timing and material consumption

• Easy to use, very low smoke and no odor

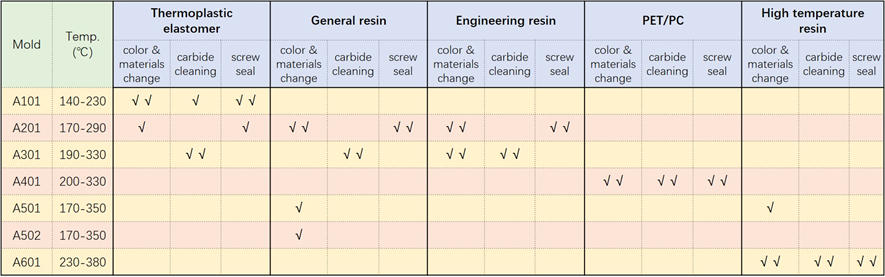

Grade Recommendation

Web | App

Web | App

My whatsapp +8613539736806