Product Overviews

High temperature plastics include a range of temperature resistant materials such as PEEK, PSU, PPO, PES, PPS, LCP, PPSU, PEI, PBI, etc, which is generally processed under higher temperature. The high-temperature purging compound introduced by PlasE Clean series can be used for most of the high-temperature resin process machines, to facilitate material switch, conduct downtime maintenance, reduce overall operation and maintenance cost.

Customer Relevance

• Is it difficult to pull out your screw and clean it after processing PEEK?

• Does it produce heavy smoke & odor when conduct screw purging?

• Is it difficult when the two plastics switch to each other?

• Is it time consuming and material demanding when you conduct color changes?

• How smooth is your operation when you switch from a high-temperature material to a low one?

Extrusion - High Temperature Plastics Purging Compound Basics

• Product appearance: granules

• Function: cleaning of barrel, screw, nozzle, die

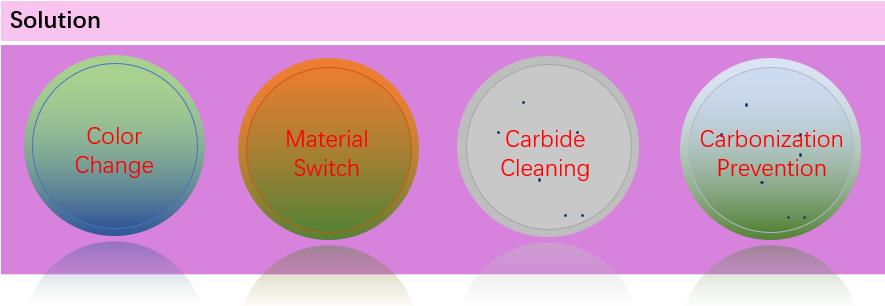

• Application: carbon cleaning, carbonization prevention, color change, material switch, downtime maintenance

• Material suitability: PEEK PSU PPO PPS LCP PPSU PEI PBI etc. high temperature plastics

• Temperature: 250-380℃

• Advantages: low smoke, high efficiency, no abrasives, no foaming

• Package:25KG/bag

• Environmental performance: very low smoke, environmental friendly

Features:

• Equipment friendly without foaming ingredients and abrasives

• Highly efficient in terms of timing and material consumption

• Easy to use, very low smoke and no odor

Grade Recommendation

Web | App

Web | App

My whatsapp +8613539736806