Product Overviews

Blow molding grade PP & PE, processed by plastic molds into plastic containers through blow molding, extrusion blow molding, or injection molding, mainly used for food and pharmaceutical packaging. The purging compound for blowing bottle machines introduced by the P series is specially used for the screw cleaning of PP and PE polyolefin plastics. It has good cleaning effects for color change, material change, carbons cleaning...

Do you have these troubles?

• When your machine stops for a while, then turn it on again,does it produce a lot of carbides?

• When the two plastics switch to each other, will it mix colors?

• When the dark color switch to light color,Is it waste a lot of materials and time?

• Is the hot runner difficult to clean?

• When high-temperature materials and low-temperature materials switch to each other, does it produce a lot of carbon?

• Are there always some diffrent color lines when the extruder is cleaned?

• Is it difficult to clean carbon and color mixing of transparent products?

Injection-blowing bottle machine PP/PE purging compound basic:

• Product shape:Granular

• Cleaner applications:screw, barrel, nozzle, hot-runner ,etc.

• Application condition:material change,color change,carbide cleaning,carbide prevention.

• Suitable for material: PP PE etc., general plastics

• Temperature: 170-320℃

• Advantages:Can be used to clean hot runners and precision dies

• Package:25KG/bag

• Environmental performance:No smoke,environmental protection

Features:

• Not foaming,without abrasives, not damage the screw

• Suitable for cleaning hot runner. not block the hot runner

• Suitable for forming cleaning,using the robot and save labor

• Save time and clean Thoroughly

• Easy to use, no smoke and no odor, food grade formula

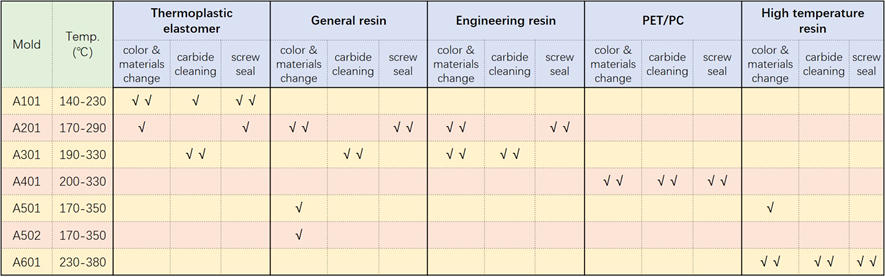

Mold:

Web | App

Web | App

My whatsapp +8613539736806