Product Overviews

PET is widely used for transparent food & cosmetic packaging requires higher hygienic standard, it is generally processed under high temperature in closed workshop where odor and smoke is not permited. General color change can be time consuming, while cleaning of the hot runner, screw and barrel is especially challenging after processing colored resins like solid white, pearl red, etc.

We recommend our customers to use PlasE Clean Series PET purging compound specially designed for PET, which can be processed automatically and continuously with effective cost and time performance.

Customer Relevance

• Do you requires smoke & odor free material when conduct screw purging?

• Is it time consuming and material demanding when you conduct color changes?

• How smooth is your operation when switching from another material to PET?

• Is it difficult to clean carbons & color residues before you produce transparent products?

• Does it produce carbons during your machine startup & shutdown?

PET Injection Purging Compound Features

• Smoke & odor free

• Continuous purging, no soak time required

• Equipment friendly without foaming ingredients and abrasives

• Highly efficient in terms of timing and material consumption

• Can be used for downtime maintenance

Basics

• Product apperance: granules

• Function: cleaning of barrel, screw, nozzle, hot-runner

• Application: carbons cleaning, carbonization prevention, color change, material switch, downtime maintenance

• Material suitability: PET

• Temperature: 260-330℃

• Advantages: suitable for various hot runners

• Package: 25KG/bag

• Environmental performance: smoke & odor free, environmental friendly

Features

• Smoke & odor free

• Continuous purging, no soak time required

• Equipment friendly without foaming ingredients and abrasives

• Highly efficient in terms of timing and material consumption

• Can be used for downtime maintenance

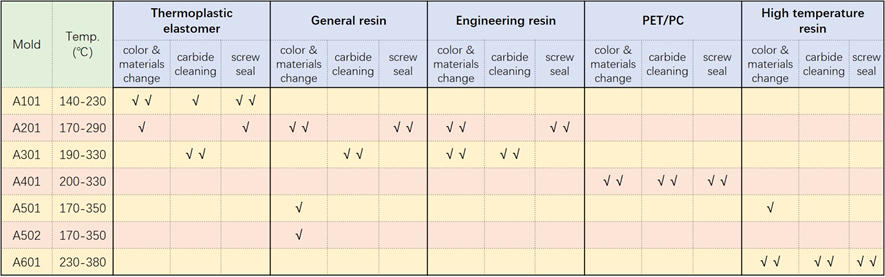

Grade Recommendation

Web | App

Web | App

My whatsapp +8613539736806