Product Overviews

When processed in an injection machine, thermoplastic elastomers such as TPE, TPR, TPV, TPEE,TPU, PVC, etc, are more susceptible to heat carbonization. In many factories, the color change of hot runner is also a very difficult problem. This will result in wasted materials & time, and increased scrap rates. PlasE Clean series purging compound can be used to quickly clean the barrel, screw and hot runner. PlasE purging compound is also very effective in removing carbons and color residues.

Injection - Thermoplastic Elastomer Purging compound Basics

• Product apperance: granules

• Function: cleaning of barrel, screw, nozzle, hot-runner

• Application: carbon cleaning, carbonization prevention, color change, material switch, downtime maintenance

• Material suitability: thermoplastic elastomer TPE, TPR, TPV, TPEE,TPU, PVC, etc,

• Temperature: 140-250℃

• Advantages: elastic, low processing temperature, very low smoke, suitable for various hot runners

• Package: 25KG/bag

• Environmental performance: very low smoke, environmental friendly

Features

• Equipment friendly without foaming ingredients and abrasives

• Highly efficient in terms of timing and material consumption

• Easy to use, very low smoke and no odor

• The purging compound is elastic. If the hot runner has some drainage opening materials, it can be easily taken out without causing unplug difficulties.

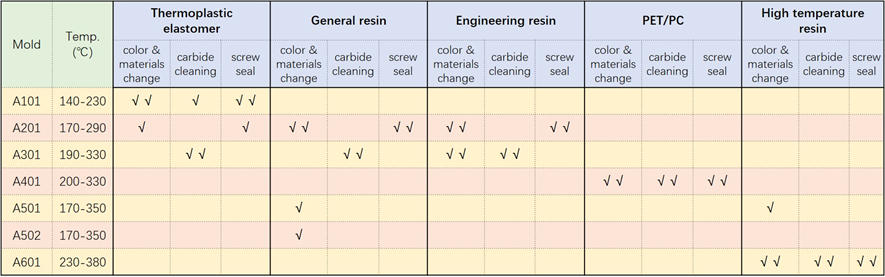

Grade Recommendation

Web | App

Web | App

My whatsapp +8613539736806