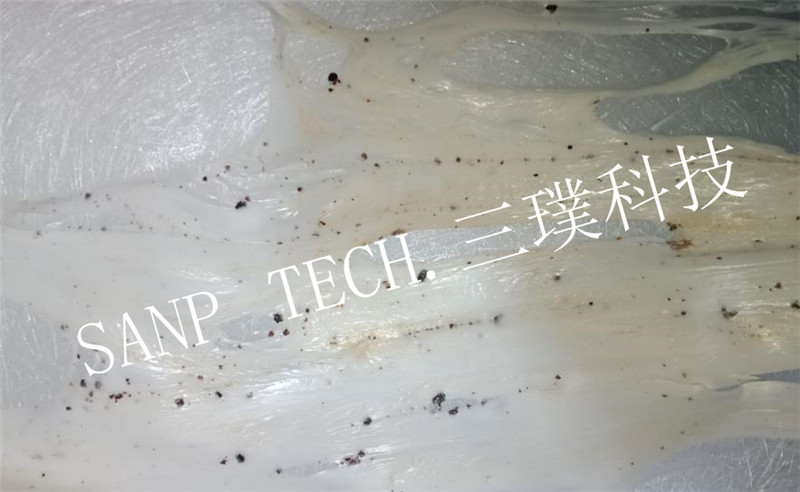

Black spots and impurities are the most common problems in the injection molding process. In a lot of injection plants, site operations need to deal with these labour-intensive and material consuming issues every day, for production efficiency sake, is there an effective way to eliminate these black spots and impurities problems?

SANP Tech. has been focusing on the thermoplastic industry for years, we provide our customers efficient solutions for screw purging.

Our observation indicated that many manufacturing sites will choose to continue the production when the scrap rate is comparatively low, which means the equipments are in the early stage of black spots and impurities problems. As the operation goes on, the black spots and impurities will start to attach to the screw, and eventually lead to the operation interruption with high finish product waste.

The fact is it is almost impossible to completely remove all the contamination at one time. In some serious cases, it is necessary to shutdown and pull out the screw for manual cleaning, or even replace the screw, which is obviously inefficient and generates much higher waste.

SANP Tech. believes that it is worth worthy to maintain the screw/ barrel/ hot runner in an ideal level, which ensures a smooth production, with effective purging solutions. Overall speaking, it obviously more effective comparing to the traditional purging with raw and/or recycle resins.

Contact us at +86 13539736806, or mail to: sanpchem01@163.com if you want to know more.

Web | App

Web | App

My whatsapp +8613539736806