A leading Chinese automotive door panel producer has been using PP resin to conduct injection machine barrel and mold hot runners color switch for years. In 2019, the company introduced a Japanese branded purging compound, which partially shortened the purging cycle but still suffering from higher dosage and thus higher cost.

The trial run of PlasE Clean purging compound (PC) was conducted at a 1600T clamping force injection machine with 5 hot runner nozzles.

Highlights of the clean cycle

l Machine: Haitian/ clamping forces 1600T/ Power 218.75KW/ manufacturing date: Apr 2018

l Operation procedure: replaced the barrel with PlasE Clean PC; increase hot runner temperature from 220℃ to 270℃, clean the nozzle one by one through open mold, replace the barrel and nozzles with production resin.

l Time & material consumption: 25KG PlasE Clean purging compound and 20KG PP resin consumed in 45 minutes

l Result: fully satisfied

| Items | Previous Purge Compound | PlasE Purge Compound |

| PC Consumption(KG) | 50 | 25 |

| PP Resin Consumption(KG) | 25 | 2 |

| Time (minutes) | 65 | 45 |

| Result | Need refinish for ~30 parts | Fully satisfied |

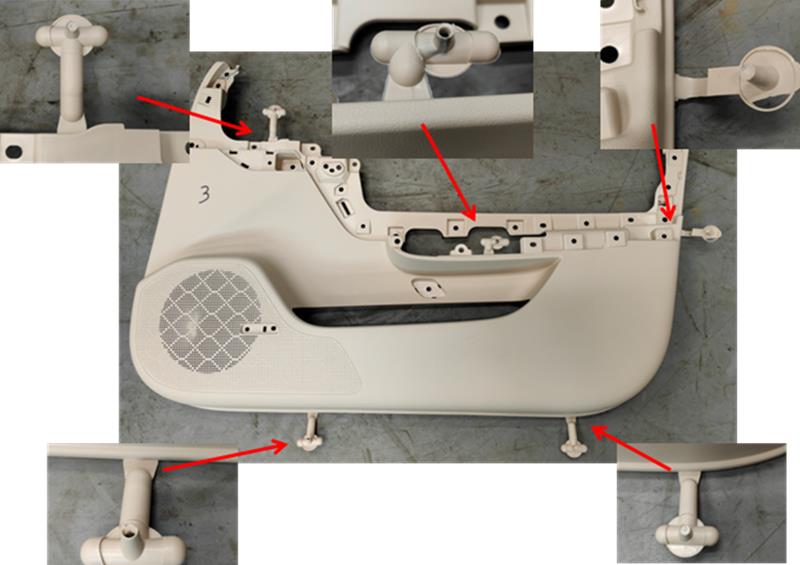

Clean progress

The finished parts is shown as below,

PlasE Clean purging compound is developed through technology innovations upon in-depth expertise and customer-oriented approach to address customer issues and challenges.

Features of PlasE Clean:

l Doesn’t contain abrasives

l Can be molded through hot runners with assistance of mold release

l Fast clean thermoplastic machines and eliminate color streaking

l Can be quick replaced by production resin

l Granules in 25KG package offered

l Grades for high operation temperature available

l Grades for black specks cleaning available

Web | App

Web | App

My whatsapp +8613539736806